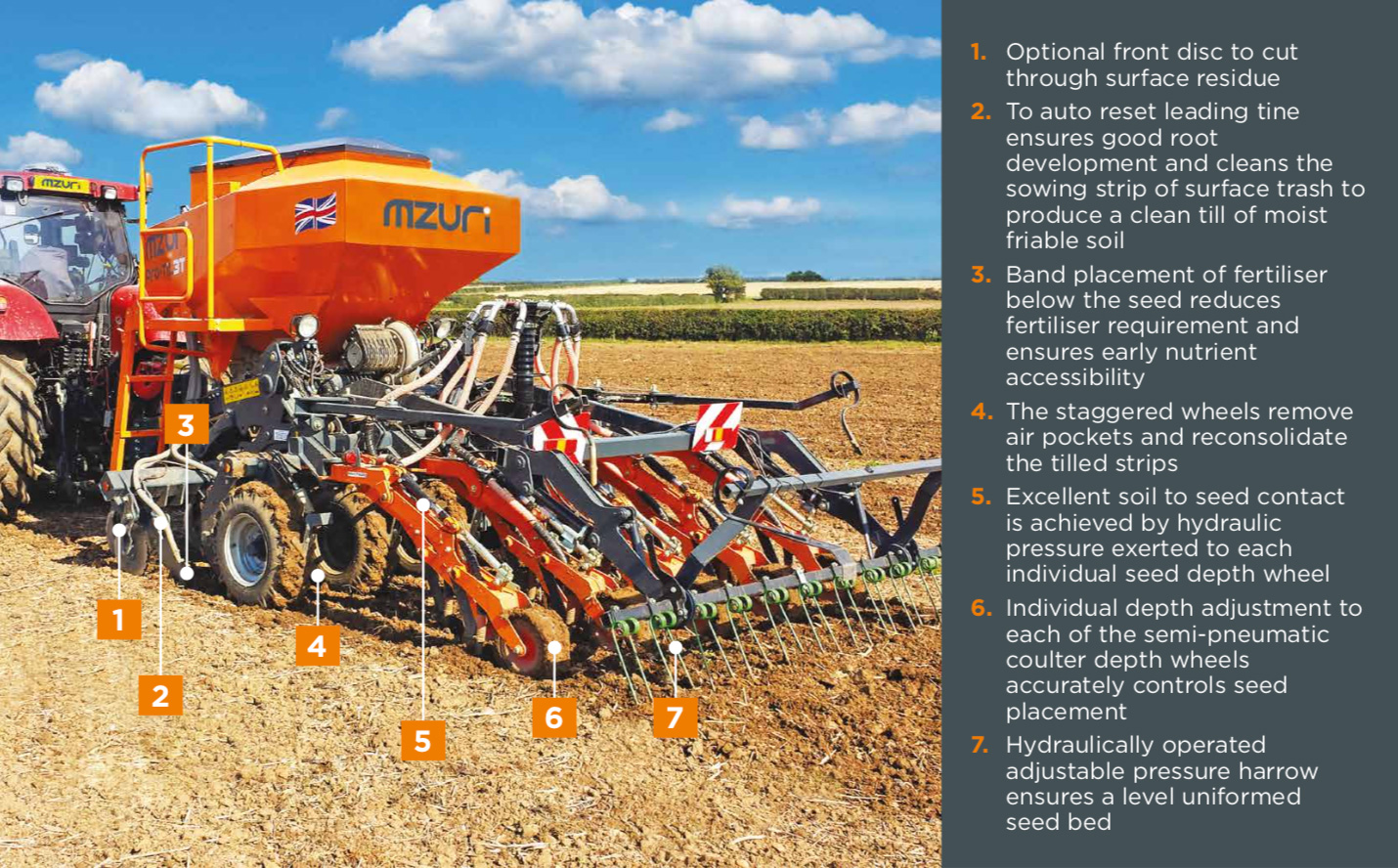

The Mzuri Pro-Til one-pass drill offers single pass establishment into stubble and cover crops without compromising the quality of the seedbed. By cultivating a small uniform till, band placing fertiliser and placing the seed at a controlled depth, the Pro-Til provides the ideal soil environment for each seed to germinate quickly and grow to achieve its full potential.

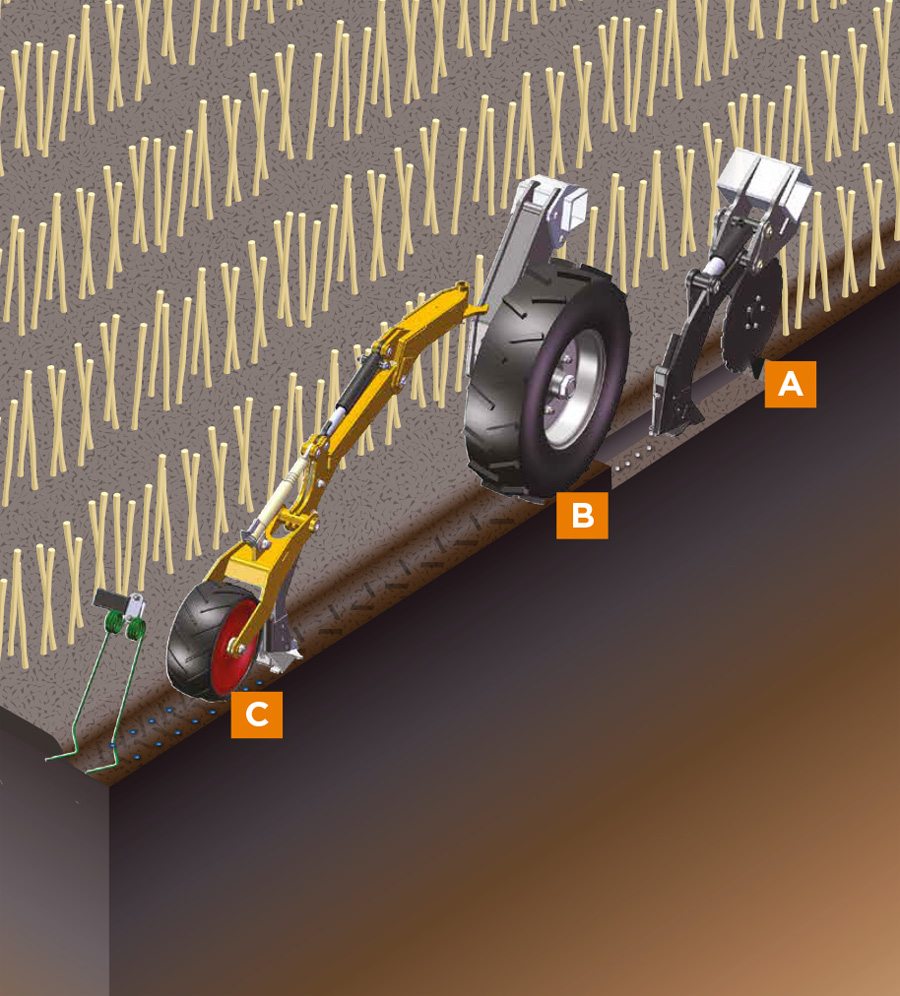

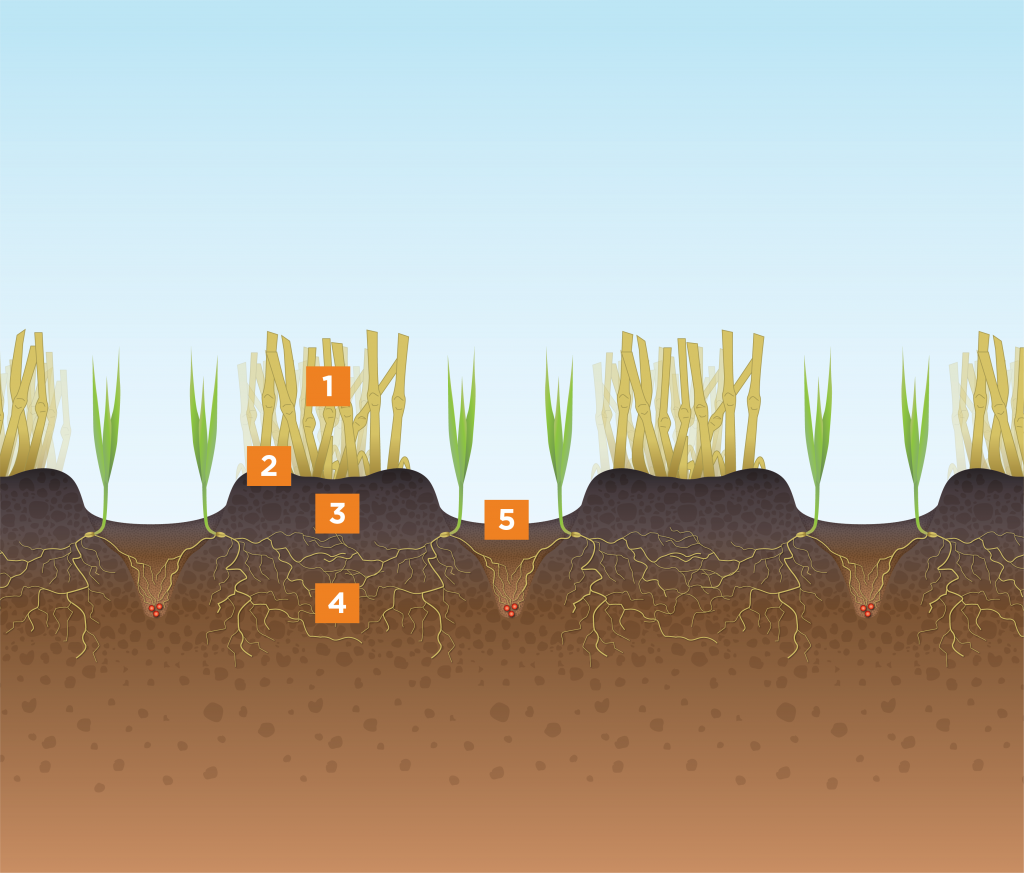

The Pro-Til’s leading coulter delivers fertiliser below the seed, clears the seeding zone of residue and leaves the crop residue on the surface between the tilled strips to retain moisture and organic matter to improve soil structure and fertility.

The tines and wheels are alternately staggered to give ample space for trash to flow through, making the Pro-Til suitable for use through a wide range of crop residues including cover crops. The independent patented pivoting coulter units are each connected to a balanced pressurised hydraulic system, which ensures an even soil pressure to each of the rear press wheels. This controlled pressure ensures an accurate seed depth and excellent soil-to-seed contact across every row.

The Pro-Til is specifically designed as a single pass ‘stubble to seed bed’ drill, however it is equally at home with inversion systems. Being so versatile, whether drilling directly into stubble, minimally tilled land or even after the plough, makes the Pro-Til the ideal machine to simplify the transition towards permanent direct drilling.

The metering unit consists of a variable speed electric motor and a gearbox driving a specific seed roller. A selection of seed rollers are provided to suit all seed types. Calibration is straightforward and accurate – simply push an electric button, weigh the collected seed and enter the amount into the control panel.

The in-cab drill management system provides on-the-move seed rate adjustment plus all of the normal essential seed drill control and monitoring functions.

Farming Equipment & Technology Fund (FETF)

Our range of Mzuri direct drills, including the Pro-Til, iPass and Pro-Til iGen are eligible for grant funding under the Farming Equipment & Technology Fund, under the Direct Drill categories. More information will be released alongside the new round of funding available from early 2024.

Sustainable Farming Incentive (SFI)

Under Defra’s new Sustainable Farming Incentive, growers can access per hectare payments for adopting sustainable farming systems including direct drilling with no prior cultivation. Our range of Pro-Til, iPass and Pro-Til iGen drills are compliant and can generate £73/ha each year over the three-year scheme. Growers utilising variable rate fertiliser technology are eligible for an additional £27/ha. More details to follow.

Key Features

Options

The Pro-Til range is available in 3, 4 and 6 metre trailed versions and a 3-metre mounted format. To add further versatility to the range, the Pro-Til is available with options including:

As well as all the benefits of a standard Mzuri Pro-Til drill, the Mzuri Pro-Til Select series can drill in a choice of narrower or wider row spacings. The wide row option makes the Select particularly suited for crops such as maize, oilseed rape and legumes. It is equally at home with drilling narrowly-spaced crops including wheat, barley and oats.

Not only does a bigger inter-row spacing allow the crops to meet their nutrient demand and produce a stronger root system, it also awards better light interception from the top of the canopy all the way down to the base of the stem. This, in return, results in a healthier, bushier and higher-yielding crop.

The free flow of air movement helps to reduce moisture and control the associated fungal diseases whereas the extra space between the leaves minimises the transfer of disease by contact.

The additional width of the inter-row, coupled with a high clearance of the tine legs, enable users to work with huge amounts of surface residue which allows to improve soil condition. The straw acts as a mulching layer to protect the soil from erosion and seals in the natural moisture, preventing the ground from drying out. It also harbours a range of beneficial fauna and helps to rapidly increase earthworm population, both of which are vital for improving soil fertility and structure.

Pro-Til Select offers a wide choice of coulter fittings which awards users the flexibility to carry out precision seeding, strip tilling and low disturbance direct drilling with just one piece of equipment, making it the ultimate one-pass drill for all combinable crops.

The Pro-Til Select is available in 3, 4 and 6 metre trailed models.

The Select range offers the following row spacings:

- 3T – 33.3cm or 66.6cm row spacing.

- 4T – 36.3cm or 72.6cm row spacing.

- 6T – 35.3cm or 70.6cm row spacing.

Topped up from the drill’s main 2800 litre seed hopper, the Xzact seed singulating metering system is an optional extra that can be fitted to most Pro-Til drills to provide non-stop seeding of precision crops including maize, sunflower and soya. The drill can just as easily be converted back into a standard Pro-Til drill for crops such as wheat, oilseed rape and beans.

The Xzact system features an electronic seed singulating unit and coulter assembly to deliver single seed placement whilst the constant hydraulic pressure exerted onto each coulter arm ensures the seeding depth accuracy.

The system uses adjustable-pressure vacuum metering to accurately space crops, regardless of the seed size. Each unit contains a metering disc and a singulator to prevent skips or doubles and is driven by an electric motor which maintains the same seeding distance at variable speeds.

Unlike with conventional singulation seeders, the mini hoppers on the Pro-Til Xzact drill are automatically replenished by a bulk fill mechanism on each metering unit directly from the Pro-Til’s main tank, thus extending the drilling time and reducing downtime.

Pro-Til Xzact features hydraulic pressure adjustment to each individual arm and a coulter-following semi-pneumatic wheel to remove air pockets whilst ensuring that the soil is not over-consolidated for compaction-intolerant precision crops.

Pro-Til Xzact delivers exceptional seeding accuracy, typically awarded by conventional precision seeding drills, in a form of a single pass drill, yet without any of the downsides. The innovative ‘one pass seed singulation’ approach eliminates ploughing and power-harrowing operations, which are widely recognised as huge contributors to erosion and loss of moisture, meaning that the soil’s natural structure can be preserved to the benefit of the crop and the environment.

- Pivoting Front Cutting Discs

- Stocks TJ8 Slug Pelleter

- Standard Harrow Bar – Shown with Avadex plates

- Double Harrow Bar

- Paddle Harrow

- Dual Tank

- Choice of Coulters